MaxCharge Technology

Less Chemical Waste

Testing by four major universities comparing ESS with conventional and air-blast sprayers shows 300% better spray penetration and coverage onto hidden areas of dense foliage. The studies also found that only 15-20% of the spray from conventional or air-blast sprayers ends up on the plants, with nearly 60% of the chemical wasted on the ground and less than 3% reaching the underside of the target and other hidden areas.

Quick Payback

Better spray coverage equates to lower chemical consumption and faster investment payback. Most users can reduce costs by 25-50% and still see effective results from their spray program.

Easy to Disassemble and Clean

MaxCharge™ nozzles are 10 times faster to clean than other electrostatic systems. Just twist off the nozzle’s cover—no tools are required. There are no small parts to lose and no wires at the tip to break.

Environmentally Sound

Reducing chemical waste and using low-toxicity chemicals make your spray environmentally safe and effective. Because ESS units allow you to spray longer with less chemical, exposure to chemical due to constant tank refills is reduced.

The MaxCharge™ Difference

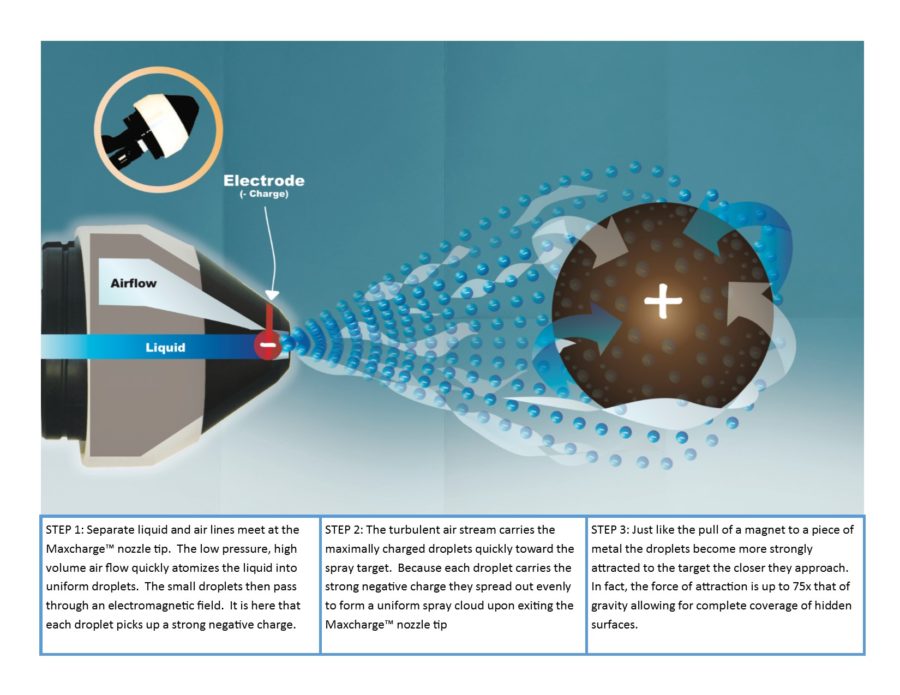

The heart of the air-assisted electrostatic sprayer is the patented MaxCharge™ “air-atomizing induction-charging” nozzle, which was invented at the University of Georgia.

Air and liquid enter the rear of the nozzle separately. The air moves through the nozzle under pressure and meets the liquid at the nozzle tip, causing the formation of spray droplets that are 30 to 60 microns in diameter. At the tip of the nozzle is a tiny electrode that applies an electrical charge to the spray. The electrical charging causes a natural force of attraction between the spray droplets and target surface, similar to the attraction between items of clothing created by the tumbling of a clothes dryer. The attraction to the target’s surfaces relates to Coulomb’s Law, which states that any two charged objects will create a force on each other. The charge on the droplets, though small, pulls the spray towards the target at 75 times the force of gravity. The spray droplets can reverse direction, moving against gravity, to coat all sides of an object.

ESS takes advantage of the principle of physics to achieve better coverage and to lessen the environmental impact by allowing smaller amounts of chemicals to be used. In addition, ESS uses air-assistance to help with spray delivery. Air is necessary in electrostatic spraying to create tiny droplets (30-60 microns, 900 times smaller than conventional sprayers) that can travel in the turbulent airstream into dense areas.

Address

62 Morrison St

Watkinsville GA 30677

Follow Us

Looking for the latest news?